As needed, when needed expertise.

Our unique approach to development and support.

B&H Flow Analytics™ bring together proven methodology, technology and engineering expertise in a collaborative process – as a valuable extension to your process and engineering resources.

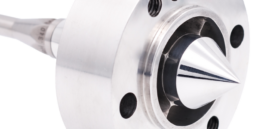

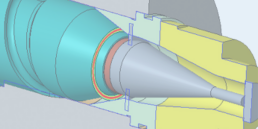

Leading companies rely on our experience in tooling design to optimize the extrusion of thermoplastics and fluoropolymers. We understand how heat, pressure, shear and velocity can impact material being extruded – and how our tooling can be optimized to control these factors.

B&H uses a transparent and collaborative approach that together with the knowledge, skills and creativity of your engineering team leverages our expertise to your advantage. Our process, developed over time with input from some of the industry’s most prominent OEMs, allows development work to be completed in substantially less time than conventional approaches.

Start-to-finish support

We work closely with your engineering team as you bring your new tooling online and fine tune as necessary to ensure best-possible performance and results. We find our process consistently produces superior outcomes. Our commitment is to deliver exceptional results for every extrusion tooling project – large or small – standard or custom.

B&H also offers comprehensive in-plant training for extrusion line workers, supervisors and material specialists, from introductory level through advanced.

In-house training provided through B&H Tool is customized to your operations and facility and is often an excellent follow-up to a technical and process analysis, assuring that new concepts and process modifications are fully understood.

B&H Tool is equipped to provide fast, expert responses needed by Maintenance and Production.

Let us know how we can help >